Ranter

Join devRant

Do all the things like

++ or -- rants, post your own rants, comment on others' rants and build your customized dev avatar

Sign Up

Pipeless API

From the creators of devRant, Pipeless lets you power real-time personalized recommendations and activity feeds using a simple API

Learn More

Comments

-

Condor328946yNo idea about mechanicals honestly 😶 but you're talking about the inside of the motor? The gears.. plastic gears hmm... Well a stepper with metal gears shouldn't be hard to source, right?

Condor328946yNo idea about mechanicals honestly 😶 but you're talking about the inside of the motor? The gears.. plastic gears hmm... Well a stepper with metal gears shouldn't be hard to source, right? -

@Haxk20 Nah.. the < €250 machines suck, you must put more €200 or €300 changing parts.

This is my first prototype... I'm learning how to make the machines, First small and veryyy cheap, next a little bigger with BJ steppers, next with aluminum frames and calibrated and then steel ones.

I did this one to learn, as It would never be good enough for me.

Already setting the pieces for the next one.

It worked well as a plotter, but the X axys was already giving problems. I may save it If i can get an equal plastic piece and do a full enclosure of the stepper guide...

Even when I do the next one, this one will always be a good drinner, as I made it portable, to work anywhere, even engraving large wood pieces.

I'll probably do one or two more like this one but with screws for engraving and drilling as it's really practical. -

@Condor No, No, the problem is the guide.

If you look at a stepper from a Cd-Rom, the guide is a plastic half piece, you put weight on it and It won't work as it has no traction.

And I don't know where to get a full enclosored guide for the stepper screw.

Luckily the motors work perfectly (do you know they are selling these for >10$ on china? Fuck them) but the plastic guides that attach to the screw are open and week, and they get hot like hell. -

I'm looking to other steppers... and I just picked the weeker one... have to start from scratch. Oh well

-

Condor328946y@GyroGearloose Aha! That's the part that I've omitted in the edit then, as I thought it'd be wrong. Well I'd suggest using metal or wood for that post then. Plastic is all fine and good up to a certain point, but for a heavy motor it'd probably be better to use something else. Metal is good because it's super rigid, or wood because it's super easy to work with.. and things like MDF or HDF are pretty strong too, especially when you use it for small areas. Of course a potential issue could be its susceptibility to heat. I'd try to run that motor on lower voltage perhaps. Otherwise you'll probably have to go with metal, and use the guides as a heatsink.

Condor328946y@GyroGearloose Aha! That's the part that I've omitted in the edit then, as I thought it'd be wrong. Well I'd suggest using metal or wood for that post then. Plastic is all fine and good up to a certain point, but for a heavy motor it'd probably be better to use something else. Metal is good because it's super rigid, or wood because it's super easy to work with.. and things like MDF or HDF are pretty strong too, especially when you use it for small areas. Of course a potential issue could be its susceptibility to heat. I'd try to run that motor on lower voltage perhaps. Otherwise you'll probably have to go with metal, and use the guides as a heatsink. -

@Condor Got better... Pinewood. My area has a very, very large area of pine woods, Plus maritime wood, don't know what you call it there. Is a mix of several types of woods stick in 1mm plates. has 10mm and the strength of a 40mm pine wood board.

For aluminium, I'm going to the local scrapyard.

Today got 2 frames I'm gonna cut and replace the Wood I was going to use. Aluminium is just so much better.

Oh, and found a real treasure... an old printer with a 500mm axis and at least two big steppers :p

About this one, found the problem, I'm replacing the X motor.

For the next one, I'll use an H structure... That's the design of the CNC I worked with and the most resilient one.

This is basically the design of the CNC without the structure:

http://vs5192xhlpxfpbo52bue0oul.wpengine.netdna-cdn.com/...

Making the Y supported by a rigid structure makes it scalable... -

Condor328946y@GyroGearloose it's actually possible to salvage materials from scrapyards? I didn't even think of that yet. Should probably inform myself at the local scrapyards about this too. Who knows what kinda treasures with just a blown fuse or burnt resistor or blown caps I'd be able to find there.. and especially for source materials, I'm sure it'd be great.. who would've thought? Thanks for the suggestion!

Condor328946y@GyroGearloose it's actually possible to salvage materials from scrapyards? I didn't even think of that yet. Should probably inform myself at the local scrapyards about this too. Who knows what kinda treasures with just a blown fuse or burnt resistor or blown caps I'd be able to find there.. and especially for source materials, I'm sure it'd be great.. who would've thought? Thanks for the suggestion! -

@Condor Lets put this way.

I was talking to the owner, A friend of mine because I worked there for 6 months, when I looked at an electronics piece...

To him, it was like €0.10 ...

Started counting, has around €100 Euros of electronics. Going to take a pic.

And the welding isn't hard to take out, it's well done with small solder spots. -

If you find a scrapyard that lets you dismount stuff, you can get large motors, like >€200 euros for 10%, electronics? you can save over 90% and some are like new, Aluminium? If it isn't bent, you can buy for 20%, 25% the price. Need a steel structure? Wanna buy it? 500€? you get the steel for 20€ ...

It's like Chinese stuff, isn't good for everything, but just walking about I got a bag of good stuff :p -

@Condor Well, went to watch a Afto tutorial on Relays :p I knew I already read about it... hehe :p This board looks like a... motor shield? could it be? I can't identify the bigger chip

-

I quit!

(for this model)

Changed the X axis stepper platform, everything set... and damaged the Z stepper motor. Pulled the wires and fucked the connections. BAH!

Edit... I'll just trade the stepper tomorrow. Not today... Poscriation time -

@Haxk20 Don't get me wrong... When I have the money I will buy a 3D Printer like that one.

But from 3D printing to milling there is a huge difference... milling machines tend to bend and squirk and move when you're pressing the material, everything wants to brake and move with the pressure. So you have a CNC with a precision of 0.01 (with luck), Ok, I know how to work with it, how much to cut on each passage and such (3 years dealing with a 3m x 1.3m table 3 axis CNC) But still, you can't really use an aluminum frame to cut steel, And I want a CNC to cut steel...

Now the problem is that I don't know yet how to make them... I know the theory... But have no practice.

So I'll build a few very cheap, One by one, Until I'm confident to build the ones I want...

At least I want a 1000mm x 1000mm x 40mm cutter (maybe hybrid with a laser) a 400mm x 400mm x 200mm for wood and a steel frame also with 400mm x 400mm x +-100mm for steel...

With those three I can make any piece for me or to sell... -

Oh, and when I have enough Machines, If I find clients for my pieces, which almost no one else makes, I may create a company to produce such pieces...

If not... I'll just use the machines to build more machines to sell online. CNC and 3D printers sell good.

My Idea is to find the right project to start a company... If the frames sell good I may even get a warehouse and employees... -

Found it...

got 5 minutes from my brother (fucker is a robotics engineer and doesn't have 15 minutes for me.... Well, 2 kids, the younger is a hand full)...

This is a controller to control two valves in a machine.

The 9V batteries are to open and close the relays.

Nice :p Love to go to the scrap yard -

How to spend €50 in a few minutes:

https://aliexpress.com/item/...

https://aliexpress.com/item/...

https://aliexpress.com/item/...

https://aliexpress.com/item/...

FUCK MAN... -

DenilSmith7019215dNow there are probably a lot of CNC companies and it’s easier to just get your part on sites like https://machiningtoday.com/ or similar

Related Rants

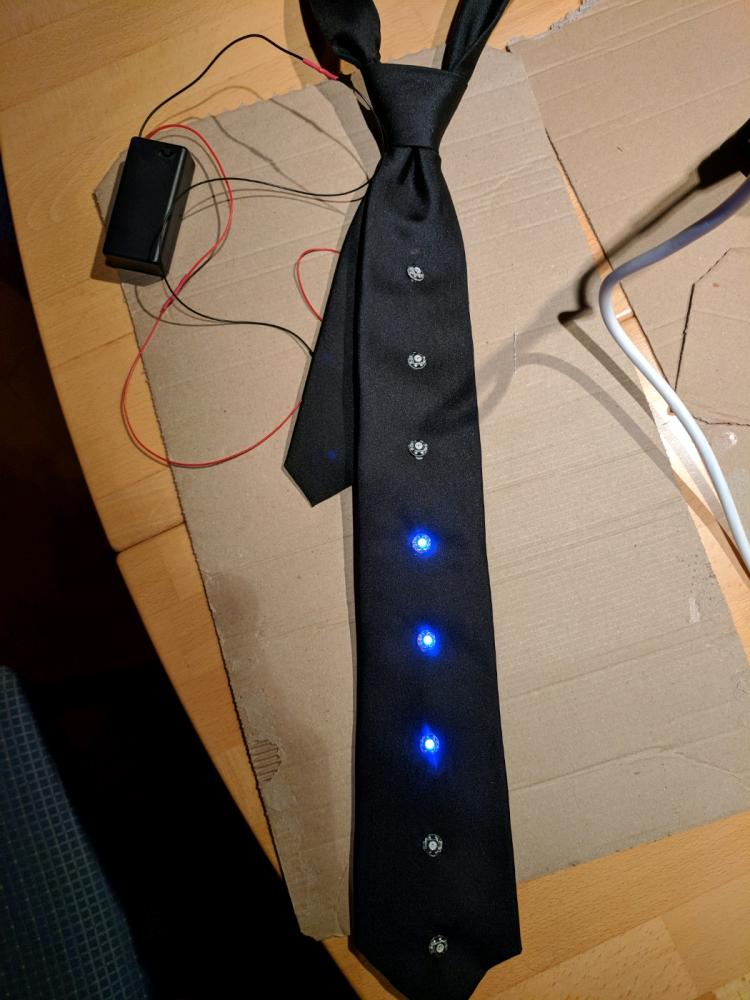

One of my personal projects.

Just trying something new ☺

One of my personal projects.

Just trying something new ☺ I have made this RGB LED tie. One of my friends and me had the idea at 2 am and now it has come to reality :D ...

I have made this RGB LED tie. One of my friends and me had the idea at 2 am and now it has come to reality :D ... Stress testing my new cnc, say Hello World roundy

Stress testing my new cnc, say Hello World roundy

FUCKKKKKK

FUCKKKKKK

everything mounted, was going to connect Z and motor...

And the fucking X stepper isn't working...

The plastic piece that made the steps is overused and can't handle the weight :(

rant

cnc

plotter

diy

arduino